If you’ve visited Elk Rapids recently, you may have noticed the tall, white, cylindrical tanks on the back side of our Production Facility. If you thought to yourself, “huh, what nice tall tubes Short’s has,” thank you! If you thought, “uh, what are these enormous cylindrical structures and how the heck do they help make my beer?” Then this is the blog post for you!

So what are these big a** objects? The tanks, specifically an Equalization and Aeration Tank, and the accompanying building addition that were recently constructed at Short’s Elk Rapids Production Facility are some of the components of our very own wastewater pre-treatment facility.

Pre-treatment facility? What is a wastewater pre-treatment facility? Essentially, it is a processing facility for wastewater. In our case, the wastewater was water that was used in the production of beer, that doesn’t actually become beer. The goal of the pre-treatment system is to clean the influent to extreme water quality and reduce our environmental impact.

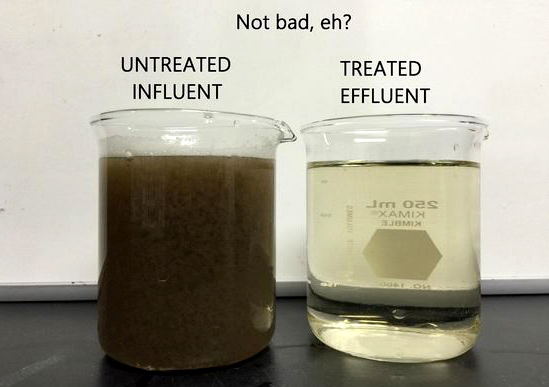

So how does this facility transform our wastewater? Water that enters our wastewater pre-treatment facility (influent) from the brewery has high concentrations of sugar, protein, and cleaning agents. The wastewater pre-treatment system utilizes microorganisms (affectionately referred to as bugs) and a filter. Wastewater is passed through a series of filters – first large and later fine grain as well as tanks filled with bugs. The microorganisms or bugs then actually eat the byproducts from our wastewater as it is moved through the filter. The result? Water that is 100% cleaner than when it entered the system with a solids content that is barely measurable, an extremely low BOD, and virtually no odor! Pretty neat, huh?

Our wastewater treatment process complements other environmentally friendly practices we’ve introduced including, design and installation of tank chilling systems that minimize energy use, using our brewhouse byproducts to make fuel ethanol and biogas, and the use of spent grain from both the Pub and Production Facility breweries by local farmers as fertilizer and animal feed. Short’s Brewing Company is also a supporter of the Clean Water Act headwaters rule.

In addition to wastewater pre-treatment and conservation practices, we take great pride in recycling materials throughout the brewing and production process, using compostable products at our Pub, using 100% compostable products at our festivals and events, purchasing renewable energy offsets, and providing support for local natural areas and trails such as the GTRLC and Glacial Hills Trail system in Bellaire, MI.

Recently, Short’s was recognized by Clean Water Action – Michigan as Innovator of the Year at the 2015 Great Lake Awards Celebration. According to Tyler Glaze, Short’s Director of Quality, Short’s wastewater pre-treatment plant produces the cleanest effluent (water that has been processed in our wastewater pre-treatment plant) in comparison to any other brewery in the mitten state. In fact, the effluent is so clean that it can be used for a variety of purposes instead of being sent to Elk Rapids Wastewater Treatment Plant including onsite irrigation.

So what’s the point? The simple truth is that not only do we brew beer in Elk Rapids and Bellaire, but we’re thrilled to be say that these are the communities where we choose to live and spend our free time. As a company, we’re making it a priority to preserve our waterways, reduce our waste, and to support the natural areas and trails we love.

What’s next? We’re excited to share with you our next big project, the installation of a solar array to power our wastewater pre-treatment plant in the coming months. Stay tuned for information about future SBC sustainability initiatives, on our blog, Short’s Cast, and our social media channels.